The 2021 UK materials shortage – time to consider the alternatives?

After a slow 12 months for the construction industry at large and for homebuilders and homeowners, in particular, things may be looking up. Building work has picked up in the first half of the year, both in the commercial sector and for private contractors and DIY work. Finally, after months of lockdown, it’s time to get to those much-needed renovations.

But as with most silver linings, this one comes on the edge of a cloud. The surge in demand, combined with supply chain disruptions, means that summer 2021 will be the most expensive time to build in over 20 years. Homeowners may have to further postpone long-planned building and renovation work or turn to alternative materials.

Only about a quarter of building materials used in the UK are imported from the trading block, but with surging demand already putting supply chains under pressure, shipping delays compound an existing shortage. According to the latest figures from IHS Markit and the Procurement Executives Group (PEG), demand for building materials in May surged at the fastest rate in 24 years.

The IHS Markit index puts the cost of materials at 83.1, the fastest surge in seven months, meaning that homeowners may be best advised to carefully consider alternatives to traditional materials. The material shortage means that timber in May cost around 80% more than it did in November 2020, steel joists have become significantly dearer, because iron ore has gone up by more than 80%, while plastics are up 60%.

The more sustainable option

The industry outlook is that the trend will hold steady well into summer and potentially later into 2021, despite the material shortage causing commercial work to grind to a halt in some cases. Industry leaders, including Duncan Brock, group director at the Chartered Institute of Procurement & Supply, calling material costs an “unfortunate spanner in the works” which might “cool the sector down a notch” later in the year.

The news may be good for the construction sector overall – more activity means higher profits, even on tighter margins, and employment is slowly returning to pre-pandemic levels. Unfortunately, homeowners may find themselves pushed out of more minor renovations by industry need for materials or, indeed, by other homeowners with a higher budget.

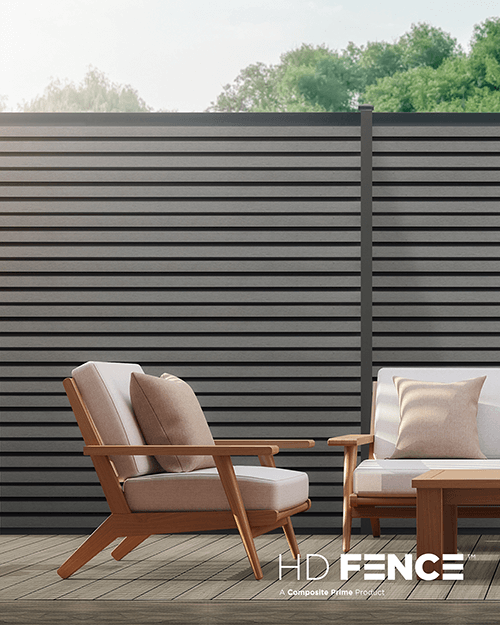

To put it simply, as timber becomes more expensive, alternatives like composite materials have become a more comparable and overall more efficient option. A quick Google search reveals that a 150mm timber board will now set you back anywhere between £14 and £24, putting the price in line with low- to mid-range hollow WPC boards. Additionally, composite materials boast a longer lifespan and better sustainability characteristics.

A way out of a crisis

One way out of a tight spot for contractors and DIY enthusiasts alike may be to take a collaborative approach with suppliers, by pacing projects and accounting for the long wait times. For contractors, leaning on strong relationships with suppliers will also be key for getting through what may prove to be an expensive second half of the year.

Turning to alternative materials will also become an increasingly appealing option, as prices fall more in line with those of timber, steel and plastic.

_recent posts

Nov 18th 2022

10 Ideas That Make Ordinary Gardens Look Luxe

Nov 11th 2022

The Best Way to Brighten Up a Shady Garden

Nov 4th 2022

Do Composite Decking and Fireworks Mix?

Oct 28th 2022

Reasons to Take Your Halloween Party Outdoors On Your Deck

Oct 21st 2022